Tobias Zöller - watchmaker

Just as a watch repair brings an old clockwork back to life, we too can reset our inner rhythm and consciously shape the flow of our lives. Because in the end, all that remains is the memory of the moments we experienced—and the beauty we found in them.

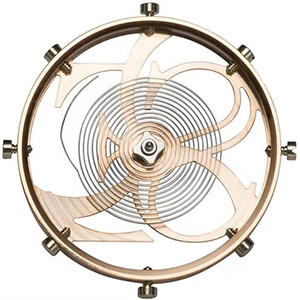

![]() My name is Tobias Zöller. I am a qualified master watchmaker with a deep passion for precise mechanics and the finest craftsmanship. For many years, I have dedicated myself to the repair, restoration, and maintenance of wristwatches and pocket watches with the utmost care. After successfully completing my apprenticeship as a watchmaker, I gained extensive experience in renowned workshops and finally passed the master craftsman examination.

My name is Tobias Zöller. I am a qualified master watchmaker with a deep passion for precise mechanics and the finest craftsmanship. For many years, I have dedicated myself to the repair, restoration, and maintenance of wristwatches and pocket watches with the utmost care. After successfully completing my apprenticeship as a watchmaker, I gained extensive experience in renowned workshops and finally passed the master craftsman examination.

My expertise ranges from historical timepieces to modern automatic and quartz watches. My calm, conscientious approach and my keen sense for technical details support me in this. My customers entrust me not only with their valuable watches, but also with true family heirlooms. My motto is that watchmaking is not just a profession, but a calling.